tube filler Tube Fill Machine for plastic laminate and aluminum tubes (up to 200 ppm)

PRODUCT DETAIL

Brief Description:

Electronic control part of linear tube filling machine: adopts 12-inch touch screen, motion controller, and 18 sets of servo bus drives; the dynamic to static ratio is increased, and the high-speed noise is less than 75 decibels.

linear tube filling machine transmission part: double-station elliptical mechanism, alloy steel integral guide rail, anti-vibration three-bearing tube cup locking mechanism of linear tube filling machine, high-speed, stable and reliable above 200 pieces/min.

Separation of areas: hose self-cleaning, two pipe boxes on one side (large operating space is more convenient), semi-automatic tube loading, automatic tube lowering, filling and sealing, servo tube discharging and other areas are separated according to GMP requirements. Meet sterility requirements。

linear tube filling machine adopted Tube loading method: 100-level laminar flow, double-station servo-driven flap, no manual contact, linear tube filling machine meets GMP sterility requirements.

Indexing mechanism: The linear tube filling machine uses a servo as the indexer, and develops differential software to increase the dynamic to static ratio, lengthen the static time of filling and sealing, and ensure that the stable speed of the equipment is above 180 tubes/min.

Benchmarking method of linear tube filling machine: dual-station servo benchmarking, bus control, timely processing of information feedback, accurate and reliable benchmarking for linear tube filling machine

Aluminum tube clamping and flattening: The tail sealing device of tube filler is clamped and flattened horizontally to reduce dust, remove air in the tube, and prevent splashing

Aluminum tube tail sealing: When sealing the tail, the folding clamp adopts bearing-guided horizontal linear movement, which is beautiful and does not pull the tube upward. It is especially suitable for three-fold tails to ensure consistent tube length.

Composite tube sealing: hot air or high frequency, imported high-frequency heating sealing instantly heats for 0.1 seconds per cycle, away from the ointment, not only saves power, the sealing is beautiful, and there is no risk of the ointment deteriorating, more in line with sterile GMP requirements

Servo filling: The tube filler adopts servo drive and double-station servo all-ceramic pump filling, which will never wear out. The tube filler adopts a special insulation pipeline design, and the insulation hose goes directly to the filling nozzle, so the filling accuracy is higher.

Discharging device: The servo ejects the hose, and then flexibly puts it into the conveyor belt to avoid collisions, ensure even spacing, and perfectly connect to the cartoning machine.

Paste transportation: The high-level tank is weighed to determine the material level. The insulation pressure of the pipeline to the filling pump goes directly to the filling nozzle. There is less paste residue in the pipeline. The distribution pipe is quickly opened to connect to the filling pump mode. The efficiency of the tube filler is greatly improved.

H. Online cleaning and sterilization: The filling parts and connecting pipes are specially designed for online cleaning and sterilization. It is simple, convenient and practical, and meets the sterility requirements. Due to the quick-connect design, it can also be easily disassembled for offline sterilization.

LFC180ABS full servo plastic tube sealing machine

| No | Parameter |

remarks |

||

| Tube diameter(mm) | 10~50 |

|

||

| Color mark positioning(mm) | ±1.5 |

|

||

| Filling capacity(ml) | 1.5~250 |

|

||

| Filling accuracy(%) | ≤±0.5-1,Calculated based on 15g product, within ±0.1g |

|

||

| Sealing method | Type A: metal tube | Single side hemming

Or saddle-shaped double-sided hemming |

|

|

| Type B: plastic pipe, composite pipe | High frequency heating sealing

Pinhole type internal hot air sealing |

|||

| Production capacity (pieces/minute) | 130-180 |

|

||

| Applicable tube material | Metal pipes, plastic pipes, composite pipes |

|

||

| tube filler power(Kw) | Type A: metal tube | 20 |

|

|

| Type B: composite pipe | 26 |

|

||

| power supply | 380V 50Hz |

|

||

| air pressure | 0.6Mpa |

|

||

| Air consumption ((m3/h) | Type A: metal tube | 10-20 |

|

|

| Type B: plastic pipe, composite pipe | 30 |

|

||

| Water Consumption(l/min) | Type B: plastic pipe, composite pipe | 12 |

15°C |

|

| Transmission chain form | (Imported from Italy) Rebar synchronous belt type (servo drive) |

|

||

| transmission mechanism | Multi-cam mechanism and servo system |

|

||

| Total weight(Kg) | 3500 | |||

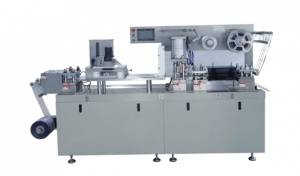

The LFC180 tube filling and sealing machine is a full-scale dual-station filling and sealing machine independently developed, designed and manufactured by our company based on the advanced models of foreign hose filling and sealing machines and combined with the global demand for tube fillers. New servo filling machine. This model is fully enclosed in stainless steel. It is suitable for filling and sealing of various specifications of sterile or non-sterile aluminum-plastic composite tubes and aluminum tubes. The design speed is 180 pieces/minute. The actual maximum normal production of the plastic tube sealing machine is The speed is 120-200 pieces/minute. The filling accuracy is ≤±0.5-1%. The sealing method is that the aluminum pipe is folded and sealed, and the aluminum-plastic composite pipe is sealed by high-frequency heating.

tube filler mainly composed of the following institutions:

tube filler Adopts hose self-cleaning function, hose conveying device, tube cup upper tube device, tube cup servo indexing mechanism, automatic hopper loading, nitrogen filling mechanism before filling, servo filling mechanism, nitrogen filling mechanism after filling, and tail sealing Mechanism (saddle-shaped three-fold tail or internal hot air heated tail sealing), you can choose a visual inspection system, a tube outlet mechanism, a weighing rejection and an information feedback system.

plastic tube sealing machine adopted clean system uses compressed air blowing and vacuum suction to clean the inside of the pipe. The depth of the blowing head into the pipe should be controllable and adjustable in a reliable way. tube filler is equipped with a sensor to check whether the operation is executed. If the operation is not executed, the machine will stop and alarm.。

plastic tube sealing machine can carry out tube are inspected before filling, and if there is a bad pipe, an alarm is issued or the machine is shut down; the inner wall of the qualified pipe is cleaned/removed by using filtered compressed air to remove foreign matter, dust, etc. Compressed air is ejected from a nozzle that descends to the bottom of the tube. At the same time, the exhaust hood is lowered to compress the open end of the hose, and the clean air is discharged from the air filter through the vacuum fan.

Detect large foreign objects in the hose and whether the hose is inverted, check whether the hose is severely deformed, and the equipment automatically shuts down.

F. Two-station servo benchmarking:

The cursor positioning of plastic tube sealing machine tubes should be controlled by servo motors, and the marking accuracy should be within ±1°; the angle of the cursor positioning can be controlled through digital display and input on the touch screen, making it easy to adjust (using color-coded photoelectricity)。

a. The double-station hose and pipe base lift share a set of lifting levers.

b. The cursor positioning of each tube of plastic tube sealing machine should be controlled by servo motor, and the marking accuracy should be within ±1°.

c. The positioning method of plastic tube sealing machine is that the tube cup drives the aluminum tube to rotate for positioning.

d. The angle of cursor positioning can be controlled through digital display and input on the touch screen, which is easy to adjust (using color-coded photoelectricity),

e. The infrared photoelectric sensor determines the correct direction of the hose. The effective distance is adjustable. When the tube does not turn correctly, the bad pipe mark can be displayed.

f. It is equipped with a sensor to check whether the operation is executed. If the operation is not executed, the machine will stop and alarm.

Filling configuration of linear tube filling machine

a. The buffer tank containing the prepared ointment and the filling pump are connected by quick installation. The air pressure inlet uses a precision pressure regulating valve to control the pressure of the material pipeline, and a plunger pump is used for fully automatic feeding; b. A pressure ultrasonic sensor is used to accurately control the liquid position, the liquid is emptied directly using the pressurization mode and the quick connection mode at the bottom of the buffer tank; c. The ointment filling machine adopts a professionally designed ceramic filling pump.

d. No tube and no filling: Two independent sets of no tube and no filling mechanism provide double guarantee.

e. The material and structural design of equipment accessories and connecting pipelines must ensure easy disassembly and assembly, no dead ends, and easy cleaning.

Smart zhitong has many professional designers, who can design Tubes Filling Machine according to the actual needs of customers

Please contact us for free help @whatspp +8615800211936

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936

-300x225.png)