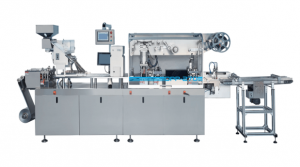

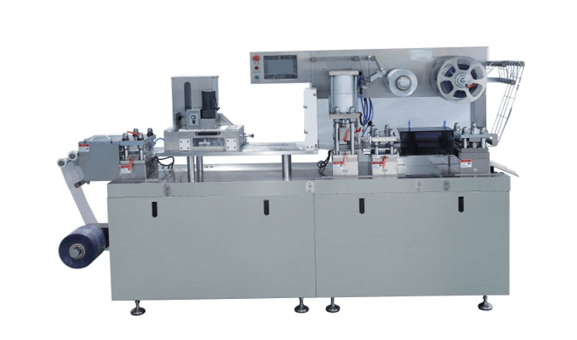

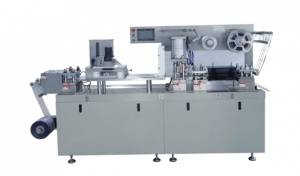

Blister packaging machinery Plastic Tray Thermoforming Machine (FSC-500/500C)

Blister packaging machinery definition

Blister Packaging Machinery,It is an automated packaging equipment mainly used to encapsulate products in transparent plastic blister. This type of packaging helps protect the product, increase its visibility, and thus boost sales. It is widely used in the packaging process of various products and can be used online with other machines such as cartoning machines.

Blister packaging machinery usually consists of a feeding device, a forming device, a heat sealing device, a cutting device and an output device. The feeding device is responsible for feeding the plastic sheet into the machine, the forming device heats and shapes the plastic sheet into the desired blister shape, the heat sealing device encapsulates the product in the blister, and the cutting device cuts the continuous blister into individual packaging, and finally the output device outputs the packaged products

Blister packaging machinery is widely used in the packaging process of medicine, food, toys, electronic products and other industries. It can produce efficiently through automated production lines, helping to improve production efficiency and reduce labor costs. In addition, blister packaging machinery also has the advantages of fast speed, high efficiency, and easy operation, and can meet the different packaging needs of different industries.

Blister pack equipment Design Features

Blister Packaging Machines has some notable features in its design make process

1. Blister Packaging Machines integrates mechanical, electrical and pneumatic design, automatic control, frequency conversion speed regulation, the sheet is heated by temperature, air pressure forming to finished product cutting, and the finished product quantity (such as 100 pieces) is conveyed to the station. The entire process is fully automated and configured. PLC human-machine interface.

2. It usually uses plate forming and plate sealing technology, which can form large-sized and complex-shaped bubbles and can meet various demanding requirements of users.

3,The processing of plate molds for blister packaging equipment can be achieved with the price of CNC machine tools, which makes its use more flexible and convenient.

4,The design features of blister packaging equipment make it an efficient and highly automated packaging equipment, which is widely used in medicine and cosmetics. In the packaging process of food, toys, electronic products, hardware and other industries。

5. It is used for molding the plastic material as PS, PVC, PET and so on, which is widely used for the minitype soup spoon, the cover of the dish such as the salver of medicine and coffee, the bottleneck of Coca-cola....

6. Blister packaging equipment equipped with electric protection to prevent default/anti phase , high/low voltage or electric leakage .Safety switch and protection cover are installed in molding chamber ,heat sealing chamber and cross /longitudinal cutting knife

Blister Packaging Machines data sheet

|

M o d e l |

FSC-500 |

FSC-500C |

|

Cutting Frequency |

10-45cut/min.(withHole-punching Station |

20-70cut/min.(without Hole-punching Statien) |

|

Material Spec |

width:480mm Thickness:0.3-0.5mm |

width:480mm Thickness:0.3-0.5mm |

|

Stroke Adjusting Area |

Stroke Area:30-240mm |

Stroke Area: 30-360mm |

|

Output |

7000-10800Plates/H |

10000-16800Plates/h |

|

Main Function |

Forming, Cutting Once Completed, Stepless Frequency Conversion, Plc Control |

Forming, Cutting Once Completed, Stepless Frequency Conversion, PLC Control. |

|

Max. Forming Depth |

50mm |

50mm |

|

Max. Forming Area |

480×240×50mm |

480×360×50mm |

|

Power |

380v 50hz |

380v 50hz |

|

Total Power |

7.5kw |

7.5kw |

|

Compressed air |

0.5-0.7mpa |

0.5-0.7mpa |

|

Air consumption |

>0.22m³/h |

>0.22m³/h |

|

Mould cooling |

Circulating Cooling By Chiller |

|

|

Noise |

75db |

75db |

|

Dimension(L×W×H) |

3850×900×1650mm |

3850×900×1650mm |

|

Weight |

2500kg |

3500kg |

|

Motor Fm Capability |

20-50hz |

20-50hz |

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936