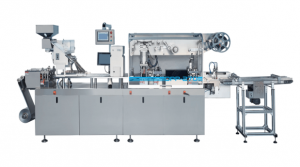

Pharmaceutical Blister machine Tablet Blister Packing Machine(DPP-250XF)

Blister machine definition

Blister machine is a machine used to produce packaging equipment for pharmaceuticals such as tablets and capsules. The machine can put medicines into prefabricated blisters, and then seal the blisters through heat sealing or ultrasonic welding to form independent medicine packages.

Blister machine can also refer to a machine that encapsulates products in transparent plastic bubbles. This kind of machine usually uses a blister molding process to adsorb heated and softened plastic sheets to the surface of the mold to form a blister consistent with the shape of the mold. The product is then placed in a blister, and the blister is closed by heat sealing or ultrasonic welding to form an independent product package.

DPP-250XF pills packaging machine series integrates mechanical, electrical and pneumatic design, automatic control, frequency conversion speed regulation, the sheet is heated by temperature, air pressure forming to finished product cutting, and the finished product quantity (such as 100 pieces) is conveyed to the station. The entire process is fully automated and configured. PLC human-machine interface.

Tablet Blister Packing Machine Workflow

1. Loading: Place the medicines to be packaged in the loading area of the machine, usually through a vibrating plate or manually.

2. Counting and filling: The medicine passes through the counting device, is counted according to the set quantity, and then is placed into the blister through the conveyor belt or filling device.

3. Blister molding: The blister material is heated and blister-molded to form a blister that matches the medicine.

4. Heat sealing The blister is sealed by heat sealing or ultrasonic welding machine to form an independent pharmaceutical package.

5. Discharging and collection: The packaged medicines are output through the discharging port, and are generally collected manually or automatically through a conveyor belt.

6. Detection and rejection: During the discharging process, there will generally be a detection device to detect the packaged drugs, and any unqualified products will be rejected.

Pills packaging machine Features

1. Fully automatic: Pills packaging machin can realize a series of operations such as automatic counting, boxing, printing batch numbers, instructions, and packing of drugs, greatly reducing manual intervention and improving production efficiency.

2. High precision: Pharmaceutical packaging machines are usually equipped with high-precision counting devices, which can accurately count and ensure the accuracy of the number of medicines in each box.

3. Multi-function: Some advanced pills packaging machines also have a variety of packaging specifications and packaging forms to choose from, which can meet the packaging needs of different drugs.

4. Safety: The design and manufacturing process of pills packaging machin strictly abide by relevant regulations and standards to ensure the safety and hygiene of drugs during the packaging process.

5. Easy to operate and maintain: Pills packaging machins usually have a simple operation interface and user-friendly design, making it easy for operators to get started. At the same time, its maintenance is relatively simple, which can reduce usage costs.

6. Environmental protection: Some advanced pharmaceutical packaging machines are also energy-saving and environmentally friendly, which can reduce the impact on the environment.

7. Integrating tray forming, bottle feeding, cartoning with compact structure and simple operation. PLC programmable control, man-machine touch interface. Designing mold according to customer requirements

Blister packing machine is mainly used in the following fields:

Pharmaceutical industry. The blister packing machine can automatically package tablets, capsules and other pharmaceutical products into sealed plastic blister shells to protect the quality and safety of the drugs.

Blister packing machine can be used for food packaging, especially solid food and small snacks. Plastic blister maintains food freshness and hygiene and provides visibility and easy-open packaging.

Cosmetics industry: Cosmetics are also often packaged using blister packing machines. This kind of packaging method can show the appearance and color of the product and improve the sales appeal of the product. Electronic products industry: Electronic products, especially small electronic components and accessories, often require safe and reliable packaging. The blister packing machine can protect these products against dust, moisture and static electricity. Stationery and toy industry: Many small stationery and toy products can be packed using blister packing machines to protect the integrity of the products and provide good display effects.

Tablet Blister Packing Machine Technical Parameters

|

MODEL no |

DPB-250 |

DPB-180 |

DPB-140 |

|

Blanking frequency (times/minute) |

6-50 |

18-20 |

15-35 |

|

capacity |

5500 pages/hour |

5000 pages/hour |

4200 pages/hour |

|

Maximum forming area and depth (mm) |

260×130×26 |

185*120*25(mm) |

140*110*26(mm) |

|

Stroke |

40-130 |

20-110(mm) |

20-110mm |

|

Standard block (mm) |

80×57 |

80*57mm |

80*57mm |

|

Air pressure (MPa) |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

|

air consumption |

≥0.35m3/min |

≥0.35m3/min |

≥0.35m3/min |

|

Total power |

380V/220V 50Hz 6.2kw |

380V 50Hz 5.2Kw |

380V/220V 50Hz 3.2Kw |

|

Motor power (kw) |

2.2 |

1.5Kw |

2.5Kw |

|

PVC hard sheet (mm) |

0.25-0.5×260 |

0.15-0.5*195(mm) |

0.15-0.5*140(mm) |

|

PTP aluminum foil (mm) |

0.02-0.035×260 |

0.02-0.035*195(mm) |

0.02-0.035*140(mm) |

|

Dialysis paper (mm) |

50-100g×260 |

50-100g*195(mm) |

50-100g*140(mm) |

|

Mold cooling |

Tap water or recycled water |

||

|

All size |

3000×730×1600(L×W×H) |

2600*750*1650(mm) |

2300*650*1615(mm) |

|

Total weight (kg) |

1800 |

900 |

900 |

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936