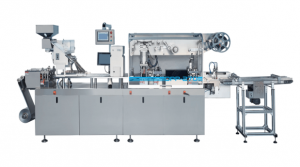

Automatic Blister Packing Machine(DPP-250XF)

Blister Pack Machine definition

Blister Pack Machine is a device used to make blister packaging. It is an automated machine commonly used in the pharmaceutical, food and consumer goods industries to package small products such as tablets, capsules, candies, batteries, etc. Blister packaging is a common form of packaging, and the Blister Pack Machine protects the product by placing it into a clear plastic blister and then sealing the blister on a corresponding backing or tray. This kind of packaging can provide good protection and sealing to prevent the product from being contaminated, damaged or disturbed by the outside world during transportation and storage. Blister Pack Machine consists of usually composed of upper and lower molds, the upper mold is used to heat-form plastic sheets, and the lower mold is used to receive and package products. flowcharting can be completed automatically through the control system, including heating, forming, sealing, and finished product discharging.

the design structure of DPP-250XF series automatic blister packing machine is meeting the standard requirements of GMP, cGMP and

the design principle of ergonomics. It adopts advanced smart driver and control technology.

Blister forming machine Design Features:

The structure is rational. And elements of electricity and gas are all from Siemens and SMC, making sure that the machine can run stably for along time.

blister forming machine Adopt humane design, combination of split, and can enter into lift and cleaning room. The installation of mold adopts fast-installing screw. Travel route adopts mathematical control. And it is convenient to change specification has vision rejection function(option), ensuring the integrie product.

Reserved the position of forming material, meeting the requirements of technological production.

Ensuring the safety of operation and each station have visible safety cover.

blister forming machine can be connected to other equipment, and work together.

Blister forming machine are designed with specific functions in mind. Key design

Features include

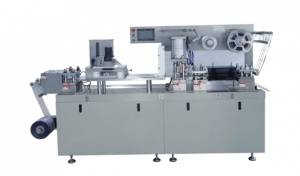

1.Versatility: The blister forming machine (DPP-250XF) is designed to handle various types of materials such as PVC, PET, and PP, allowing flexibility in packaging different products.

2.Precision and Accuracy: The blister forming machine (DPP-250XF) is equipped with a precise heating and cooling system to ensure accurate temperature control of blister forming. This ensures consistent, uniform blister shape and size

3.High Speed: The blister forming machine (DPP-250XF) is capable of high production speeds, thereby increasing output and efficiency. They can process multiple blister cavities simultaneously, reducing cycle times and increasing productivity

4. Safety Features: Blister molding machines are designed with safety features to protect operators from potential hazards. These include emergency stop buttons, safety interlocks and guards to prevent accidents during operation. Overall, the blister forming machine (DPP-250XF) provides reliable, efficient and high-quality blister packaging solutions. Their versatility, precision and ease of operation make them essential equipment in various industries.

Blister packing machine market application

Blister packing machine is mainly used in the following fields:

1. Pharmaceutical industry:The blister packing machine can automatically package tablets, capsules and other pharmaceutical products into sealed plastic blister shells to protect the quality and safety of the drugs. In addition, various management labels and security seals can also be added during the packaging process to improve the traceability and anti-counterfeiting performance of drugs.

2. Food industry: blister packing machine can be used for food packaging, especially solid food and small snacks. Plastic blister maintains food freshness and hygiene and provides visibility and easy-open packaging.

Cosmetics industry: Cosmetics are also often packaged using blister packing machines. This kind of packaging method can show the appearance and color of the product and improve the sales appeal of the product.

3.Electronic products industry: Electronic products, especially small electronic components and accessories, often require safe and reliable packaging. The blister packing machine can protect these products against dust, moisture and static electricity.

4.Stationery and toy industry: Many small stationery and toy products can be packed using blister packing machines to protect the integrity of the products and provide good display effects. In short, blister packing machine has a wide range of applications in many industries and can provide efficient, safe and beautiful packaging solutions.

Tablet blister machine Technical Parameters

| Material Width | 260mm |

| Forming Area | 250x130mm |

| Forming Depth | ≤28mm |

| Punching Frequenc | 15-50Times/minute |

| Air-Compressor | 0.3m³/min 0.5-0.7MPa |

| Total Powe | 5.7kw |

| Electric Power Connection | 380V 50Hz |

| Weight | 1500kg |

Products categories

-

E-mail

-

Phone

-

Top

0086 15800211936

0086 15800211936