When some customer want to use weight model for Vacuum Homogenizer Mixer Machine in order to make the super quality personal care product and high automatic control system , want to use the weight model for loading system .but most manufacture ignore the weighing module the requirement for Vacuum Homogenizer Emulsifier tank design requirement Here is the base requirement for Vacuum Homogenizer Emulsifier tank design

Vacuum Emulsifying Mixer Machine tank design requirement

As part of the weighing system, container equipment such as material tanks should also meet the corresponding structural requirements. The requirements are as follows:

describe

schematic diagram

Lug support: It is recommended to do local reinforcement in the lug part, including tank reinforcement and lug reinforcement; the angular deformation of the lug bottom plate under full load conditions is less than 0.5 degrees.

equipment support structure

Outrigger support: From no load to full load, the flexible deformation of the outrigger should be less than or equal to 1/1000. If the rigidity of the outrigger is poor, it is recommended to strengthen the outrigger, such as adding diagonal bars and transverse bars.

Skirt support: The strength of the skirt steel structure must meet the flexural deformation between adjacent supporting points under full load within 1/1000.

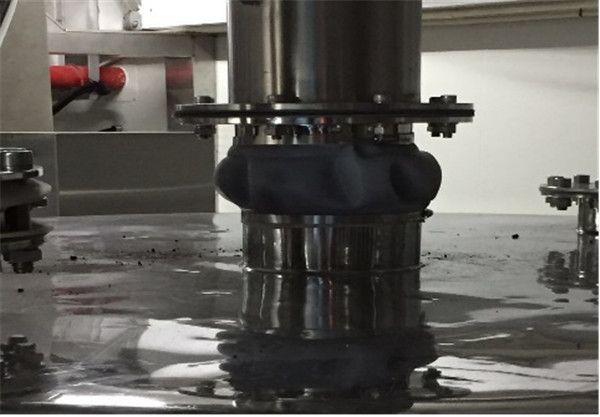

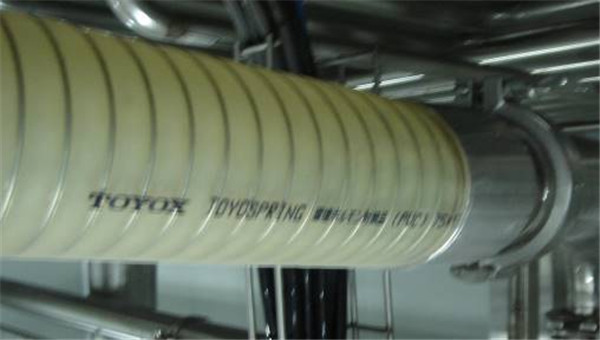

pipe connection Vacuum Emulsifying Mixer Machine tank

The pipes connected with the metering tank need to be connected with hose, hose can be selected according to the specific technological requirements, such as bellows, rubber flexible pipes, etc.

Hose Basic requirements:

1) It is recommended that the hose should be longer than or equal to 10 times the pipe diameter (it can be changed according to the actual situation, but not less than 5 times the pipe diameter).

2) The hose should be installed horizontally, not in the vertical section

3) The hose should be in a natural state and should not be significantly stretched or compressed

4) If there are special requirements for high temperature and high pressure sanitation, please select the hose that meets the requirements

5) On the premise of meeting the process requirements, it is recommended to choose the hose with better flexibility

In addition to hose connection for powder material, casing can also be considered

Smart Zhitong has many years of experience in the development, design and production of Vacuum Emulsifying Mixer Machine and the machine capacity from 5L to 18000L also Vacuum Emulsifying Mixer Machine Vacuum Emulsifier Machine for loading system

If you have concerns please contact

Post time: Oct-19-2022