In Line Homogenizer, its basic principle is the same as that of a general emulsifier. It uses the high-frequency hydraulic shear and high linear speed brought by the high-speed rotation of the rotor to cause the material to be centrifugally extruded in the narrow space between the rotor and the stator. Under the combined effects of , friction, collision, etc., they are evenly distributed with each other, and with the addition of suitable emulsifiers, the two substances that are originally immiscible can be instantly and evenly emulsified, thereby obtaining a stable product.

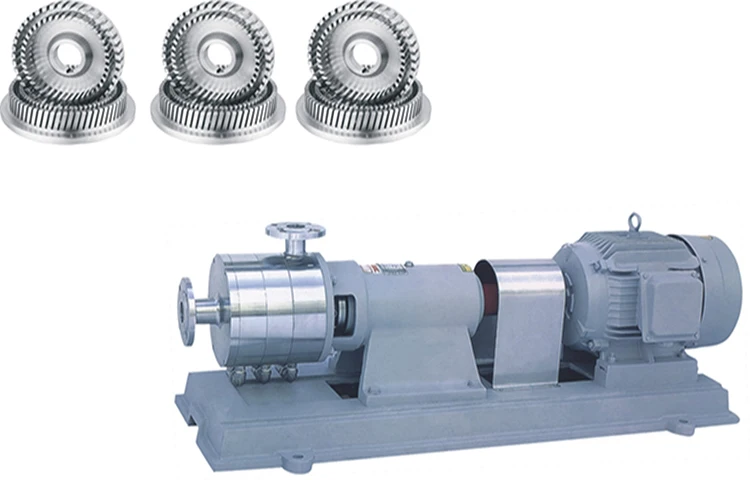

The pump head of the Inline Homogenizer is mainly composed of a stainless steel rotor and stator. The rotor and stator are made of stainless steel. This material is wear-resistant and not easy to rust. This will better subdivide some oxidizing liquids without causing damage to the pump body.

Inline Homogenizer can be used for continuous emulsification or dispersion of a variety of liquids, and at the same time, it can transport low-viscosity liquids over short distances. It can also achieve the mixing of powder and liquid, so inline homogeniser is widely used in daily chemicals, food, medicine, chemical industry, coatings and other fields.

The working principle of Inline Homogenizer is the process of uniformly, quickly and efficiently transferring one phase or multiple phases (liquid, solid, gas) into another mutually immiscible continuous phase (usually liquid). Under normal circumstances, each phase is immiscible with each other. When external energy is input, the two materials recombine into a homogeneous phase. Due to the strong kinetic energy caused by the high tangential speed and high-frequency mechanical effect generated by the high-speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, and impact in the narrow gap between the stator and the rotor. The combined effects of tearing and turbulence form suspensions (solid/liquid), emulsions (liquid/liquid) and foams (gas/liquid). As a result, the immiscible solid phase, liquid phase, and gas phase are instantly uniformly and finely dispersed and emulsified under the combined action of corresponding mature processes and appropriate amounts of additives. After high-frequency cycles, stable and high-quality products are obtained.

Features of in Line Homogenizer: 1. Narrow particle size distribution range and high uniformity; 2. Precision-cast integral frame and each rotor that has undergone precision dynamic balance testing ensure low operating noise and smooth operation of the whole machine; 3. It is not easy to produce hygienic dead corners, and materials can be dispersed and sheared through crushing; 4. Eliminate quality differences between batches; 5. It has the function of short-distance, low-lift transportation; 6. Cartridge-type mechanical seals ensure that materials are not easy to leak; 7. Can realize automatic control; 8. Large processing capacity, suitable for industrial online continuous production; 9. Time-saving, efficient and energy-saving.

Smart Zhitong has many years of experience in the development, design in Line Homogenizer

for many years

If you have concerns please contact

@Mr carlos

WhatsApp wechat +86 158 00 211 936

Post time: Dec-05-2023