Rub filling tshuab yog dab tsi?

Tshuab Sau Cov TshuabPuas yog hom tshuab tshuab tshwj xeeb siv los sau ntau yam ntaub ntawv (xws li tom ntej, kua, tshuaj pleev, thiab lwm yam) rau hauv cov leeg mos. Lub raj filling tshuab yog hom khoom siv uas ua tau lub luag haujlwm tseem ceeb hauv ntau kev lag luam. Tshuab High efficiency, Ruaj Ntseg thiab Muaj Kev Ntseeg Tau Los Ntawm Machine Ua Si Tube Ntawm Cov Tube Muag Khoom Siv Pauv Kev Lag Luam

RAJ FAWL MACHINERYYog siv dav hauv cov tshuaj pleev ib ce, tshuaj, khoom noj khoom haus, tshuaj txhua hnub thiab lwm yam kev lag luam. Machinery tuaj yeem sau qee cov khoom siv rau hauv cov txheej txheem qub. Machinery tuaj yeem txhim kho kev ua haujlwm ntau dua thiab txo cov nqi ua haujlwm. Nyob rau tib lub sijhawm, cov tshuab ua tau kom paub meej tias qhov ruaj khov thiab sib xws ntawm cov khoom lag luam zoo.

A.Cov Khoom Txhuas: Tsis siv neeg lub raj filling tshuab tuaj yeem ntim cov tshuaj pleev ib ce xws li cov tshuaj nplaum, cov tshuaj pleev cov tshuaj pleev thiab cov tshuaj pleev cov tshuaj pleev ib ce, ntxiv rau hauv cov hlab rau hauv cov hlab. Xws li cov khoom lag luam feem ntau muaj qee yam viscosity thiab yuav tsum muaj qhov system metering metering thiab kev ua tau ruaj khov.

B.Cov khoom ua kua:Raj filling tshuab tuaj yeem sau cov khoom ua kua. Cov khoom ua kua muaj cov muaj zog fluidity, tab sis puv tshuab kuj tseem tuaj yeem coj lawv. Piv txwv li, qee cov tshuaj pleev ib ce ua kua, cov ntsiab lus daws teeb meem lossis khoom noj. Thaum sau cov khoom rau hauv cov hlab, tshuab yuav siv cov qauv tshwj xeeb kom ntseeg tau qhov tseeb ntawm cov khoom siv tshuaj thiab qhov xwm txheej ntawm kev sau .. ·

C.Cov Khoom Siv Uas Muaj Vis:Raj muab muab ua kom muab tub luam, cov nplaum lossis cov khoom noj uas muaj ntau dua, tab sis los ntawm kev hloov kho cov khoom noj khoom haus uas muaj peev xwm ntau dua tuaj yeem ua tiav cov khoom siv tau zoo thiab raug.

2. Lwm cov khoom siv:Raj filling tshuab tuaj yeem lis txuas ntxiv rau cov pastes sib xyaw ua ke, cov khoom siv tau ua kua rau saum toj no, cov ntaub pua plag kuj tseem yuav tau kho raws li cov ntaub ntawv tshwj xeeb los sau lwm cov ntaub ntawv. Piv txwv li, qee cov hmoov tshwj xeeb-lub hom phiaj, granules lossis sib xyaw, thiab lwm yam.

Qhov zoo dua ntawm lub tshuab nqus hluav taws xob filling tshuab yog tias nws tuaj yeem hloov kho cov kev xav tau ntawm cov khoom siv thiab cov khoom siv tib yam, ruaj khov thiab cov txheej txheem khaws cia. Los ntawm meej sau ntsuas ntsuas thiab kev ua haujlwm tsis siv neeg, yog ua kom cov raj hauv txhua lub raj, yog li ua kom muaj kev ruaj ntseg thiab sib luag ntawm cov khoom lag luam.

A.Aluminium Yas Composite Tube (ALL)

Aluminium Yas Composite Raj yog lub ntim ntim ua los ntawm txhuas ntawv ci thiab zaj duab xis los ntawm kev sib txuas thiab cov txheej txheem sib xyaw ua ke, thiab tom qab ntawd ua tiav lub raj xa khoom siv lub tshuab. Nws cov qauv ib txwm muaj PE / PE + EAA / PE + AAA / PE. Aluminium Yas Composite Raj feem ntau yog siv rau pob tshuaj pleev ib ce nrog cov phiaj xwm theem siab thiab cov teeb meem. Nws cov txheej txheem barrier feem ntau yooj yim txiv ntawv ci, thiab nws cov cuab yeej teeb nyob ntawm tus pinhole degree ntawm txhuas ntawv ci. Nrog rau kev txhim kho kev txuas ntxiv ntawm cov thev naus laus zis, cov tuab ntawm cov khoom ci txhuas ntawm cov khoom siv txhuas kom tau txo qis ntawm 40μm rau 12μm, lossis lwm yam 15μm, uas tau txais txiaj ntsig zoo.

Tam sim no, raws li lub raj molding cov ntaub ntawv, cov hlab yuav raug faib ua cov pawg hauv qab no hauv kev ua lag luam.

A, tag nrho cov yas yas cov raj

Tag nrho cov khoom siv yas faib ua ob hom: tag nrho cov hnab yas uas tsis muaj-thaiv sib xyaw ua ke hose thiab tag nrho cov khoom siv yas sib xyaw ua ke hose. Tag nrho cov hnab yas uas tsis muaj-thaiv sib xyaw ua ke yog feem ntau siv rau kev ntim khoom qis qis-kawg-siv cov tshuaj pleev ib ce. Txhua hom yas thaiv cov raj muaj sab sib xyaw muaj sab seams thaum lub raj tsim, yog li nws feem ntau yog siv rau ntim nruab nrab- thiab cov tshuaj pleev ib ce kom tsawg. Cov txheej txheej yuav tuaj yeem yog cov khoom siv sib xyaw ntau uas muaj EVOH, PVDC, oxide-coated tsiaj, thiab lwm yam.

B, yas co-extrusion Tube

Yas co-extrusion raj yog lub raj nrog ntau txheej txheej txheej tsim los ntawm extruding ob lossis ntau cov ntaub ntawv yas ntxiv nyob rau tib lub sijhawm los ntawm co-extrusion tshuab. Cov hose no muab cov yam ntxwv sib xyaw ua ke ntawm ntau cov ntaub ntawv, xws li cov cua sov ua kom tsis kam, thiab lwm yam.

C.pure aluminium raj

Cov khoom siv txhuas yog extruded los ntawm ib tug extruder los ua lub raj ntawm qhov xav tau cov duab thiab qhov loj me.

Cov taub hlau yeeb nkab thiab cov raj muaj peev xwm ntawm kev ua lag luam

Tube size in diameter :Φ13、Φ16、Φ19、Φ22、Φ25、Φ28、Φ30、Φ33、Φ35、Φ38、Φ40、Φ45、Φ50、Φ55、Φ60

Tube filling muaj lub ntim muaj peev xwm muaj peev xwm ntim: 3G, 8G, 10G, 100g, 1G, 150G, 30G, 1X, 180G, 30G, 180G, 200G, 250G, 250G

1.Determine hom khoom koj npaj los sau

As there are many product can use the tube filling machine, such as ointments, creams, gels, and liquid medications lotions, foundations, lipsticks, and serums condiments, sauces, spreads so , so it is important to understand what type of material needs to be filled before selecting tube filling machine . Nws yog qhov zoo dua paub koj cov khoom viscosity thiab tshwj xeeb kev nqus.

Tam sim no, hauv kev lag luam, muaj ob peb hom filling tshuab raws lub raj filling ceev

Nruab Nruab Raj raj raj raj: Qhov filling machinery yog haum rau nruab nrab ntawm cov khoom siv

Cov. 1.Nws tuaj yeem ua kom muaj qee yam kev ua tau zoo thaum tswj hwm siab thiab hloov tau. Feem ntau,

2 lub raj ntim cov tshuab txais, thiab cov tshuab txais teb phaj lossis kab tawm ntawm kev tsim tsav, uas yog siv hauv cov lag luam nruab nrab

.3 Kev ua tiav lub peev xwm yog hais txog 80-150 raj filling ib feeb

Kev siab ceev raj filling tshuab: Tsim rau huab hwm coj ntau lawm,

1.Qhov tshuab yog feem ntau tau tsim los sau cov kav dej uas muaj txog 3.4 6 txog 8 nozzles. tshuab yuav tsum tau lees txais cov qauv kab, tag nrho servo tsav tsim.

2, Kev muaj peev xwm puv yog kwv yees li 150-360 filling ib feeb, nrog kev ceev ntau lawm. , tuaj yeem txhim kho kev ua haujlwm zoo,

3.Machine suab nrov heev, tab sis tej zaum muaj qee yam kev xav tau rau cov kev qhia tshwj xeeb thiab cov khoom siv ntawm cov hlab

LOW ceev lub raj filling tshuab:

1.suitable rau me me sib txawv lossis kuaj ib puag ncig ib puag ncig, qhov puv ceev kom qeeb,

2.Generally saws cov filling nozzle tsim tab sis lub tshuab ua haujlwm yog hloov tau, haum rau ntau yam ntawm cov leeg,

3.Qhov nrawm yog hais txog 20 ---- 60 raj filling ib feeb, tsuas yog siv rau cov chaw lag luam me me

Muaj ntau ntau yam cov raj khoom ntawm kev ua lag luam, feem ntau yog aluminium composite raj, tag nrho cov yas sib xyaw ua yas, yas co-extruded raj. Koj tuaj yeem txiav txim siab sab hauv cua sov, ultrasonic thiab siab heev siv tshuab sealing. Ntshiab txhuas raj xav tau los txiav txim siab kev nqis tes ua qhov chaw sib khi khi

Raj filling ntim yuav txiav txim siab filling dosing system lub configuration ntawm lub tshuab raj muab lo rau lub tshuab raj. Muab tub lim rau ntawm kev ua lag luam sau ntim. Filling dosing system sau muaj peev xwm thiab raug txiav txim saib lub raj filling machine zoo

| Sau ntau | Kev ntim khoom muaj peev xwm | Piston Inch |

| 1-5ml | 16 hli | |

| 5-25ml | 30mm | |

| 25-40 ML | 38mm | |

| 40-100ml | 45 hli | |

| 100-200ml | 60mm |

Rau qee lub raj ntim khoom muaj peev xwm tshaj 200ML cov kev tshuaj pleev qhov chaw yuav tsum tau kho rau lub raj raj ua tshuab

Cov ntawv sib khi ntawm lub raj filling tshuab tuaj yeem raug kho tau raws li cov khoom lag luam sib txawv thiab cov qauv tsim nyog. Cov khoom sib khi ua ke suav nrog txoj cai ncaj, ncig kaum (r kaum sab xis) thiab arc lub kaum ntse ntse), thiab lwm yam.

1.Txoj Hmoo Lub Tshuab Ntim Ntses Ciaj Ntaus:

Rau lub raj filling machinery, txoj cai-lub suab sib khi yog ib qho ntawm cov kev sib khi ib txwm sib khi, thiab nws tus Tsov tus tw lub ntsej muag yog txoj cai. Txoj cai-lub kaum ntse ntse muab cov lus pom yooj yim, tab sis qee kis nws yuav tsis yog puag ncig txaus thiab yuav hnov me ntsis txhav.

2.Round Kaum (R ces kaum) Sealing Raj Ntaus Tshuab

Sib npaug kaum tsev kaum kev txiav hais txog kev tsim tus Tsov tus tw ntawm lub raj rau hauv cov duab sib npaug. Piv nrog txoj cai-lub kaum ntse Lub ces kaum sib sau yog visually softer thiab txhim kho qhov kev ua kom zoo nkauj zuag qhia tag nrho thiab xav tau ntawm cov khoom.

Arc lub kaum sab xis (sector-puab) xaus cap:

ARC Kaum (Sector-puab) tus Tsov Tus Tsov Tus Tsov Tov yog ib tus Tsov Tus Tsov Ntxoob Sib Tw rau Lub Tshuab Raj Ferting Nws tus Tsov tus tw duab yog arc-puab, zoo ib yam li ib qho kev tsim qauv, vim tias Arc Kaum Kaum Tsim yog kev nyab xeeb thiab zam qhov kev puas tsuaj los ntawm cov fab ntse. Lub arc Kaum tus Tsov ntawm kev sib khi tsis yog tsuas yog zoo nkauj xwb, tab sis kuj ua raws li kev tsim kho ergonomic, uas txhim kho cov khoom lag luam.

Ib qho ntxiv, cov tub yees muab tub ua ke siv tau tuaj yeem paub txog kev hloov kho ntawm ntau yam qauv, xws li cov qauv ntsug, qauv, thiab lwm yam tuaj yeem tsim ncaj qha hauv cov txheej txheem sib khi yam tsis muaj txheej txheem tom ntej.

Ntxiv nta rau cov raj fuive tshuab:

Xav tau cov raj ntawm kev ntxuav tus kheej, ntxiv cov tshuaj nitrogen rau kev tiv thaiv cov khoom lag luam tsim, muaj plua plav. ua kom sov ua kom tiav txheej txheem. Tov Khoom Rau Hopper Thiab Zoo Xovxwm Filling?

Vim li cas thiaj li xaiv US rau lub raj filling tshuab

Zhitong tuam txhab ua ib qho ntawm cov noog ntim tshuab chaw tsim tshuaj paus kev cai ntau tshaj 2000 cov neeg siv khoom hauv ntiaj teb thiab peb muaj ntau qhov zoo raws li kev cuam tshuam

A.Professional technology thiab kev paub nplua nuj

Kev lag luam-coj thev naus laus zis: Zhitong tau nce siab txog kev sau thiab sib khi thev naus laus zis, uas tuaj yeem ua kom muaj kev ua haujlwm siab thiab muaj txiaj ntsig zoo sau cov raj raj ntawm raj tshuab raj.

b. Kev nplua nuj kev paub: tom qab xyoo ntawm kev sib sib zog nqus hauv lub raj raj filling thiab peb tuaj yeem muab cov neeg siv khoom siv cov kev xav tau uas zoo tshaj plaws lawv cov kev xav tau.

C.Wide qhov kev siv tau: Peb lub raj filling rau ntau yam tshuaj noj xws li tshuaj, tshuaj pleev ib ce, thiab lwm yam cov khoom lag luam sib txawv.

D.Muliple cov qauv xaiv los ntawm: Peb muab cov raj muab tub lim los ntawm: peb muab cov khoom siv raj thiab cov qauv tshwj xeeb kom tau raws li cov khoom siv sib txawv uas tsim tawm thiab cov raj sib txawv.

e. RAJ FILLING MACHINE MUAJ SIAB LOS THIAB HIGH EFFICI

F.Pe siv cov tshuab siab heev thiab tswj cov tshuab rau raj filling tus nqi yog qhov tseeb thiab txhim kho cov khoom tsim nyog rau 99.999%

g. Kev tsim tawm tau zoo: Peb lub raj ntim tshuab muaj qhov siab ntawm kev siv tshuab, uas tuaj yeem txhim kho kev ua haujlwm ntau dua, txo cov nqi ntau lawm thiab txo qis.

h. Cov Khoom Siv Zoo: Peb cov raj muab ua ke siv lub tshuab siv cov khoom siv zoo thiab cov khoom sib xyaw kom ntseeg tau tias qhov ruaj khov thiab ruaj khov ntawm lub raj muab tub luam.

I.Multiple Kev Nyab Xeeb Kev Tiv Thaiv: Lub raj filling tshuab yog nruab nrog kev tiv thaiv kev nyab xeeb, lub qhov rooj qhib kev nyab xeeb, kom muaj kev nyab xeeb thiab muaj kev ruaj ntseg ntawm cov txheej txheem ntau lawm.

j.Re greatural qauv tsim qauv: lub raj filling cov qauv tsim muaj thiab huv, thiab yooj yim rau kev tu txhua hnub thiab upkeep ntawm cov cav tov ..

k. Yooj yim rau kev ua haujlwm: Raum Foob Tshuab muaj cov phooj ywg zoo nkauj, muab tub lim yog yooj yim thiab yooj yim ua haujlwm, txo qis kev ua haujlwm thiab tus nqi ntawm kev kawm ua haujlwm.

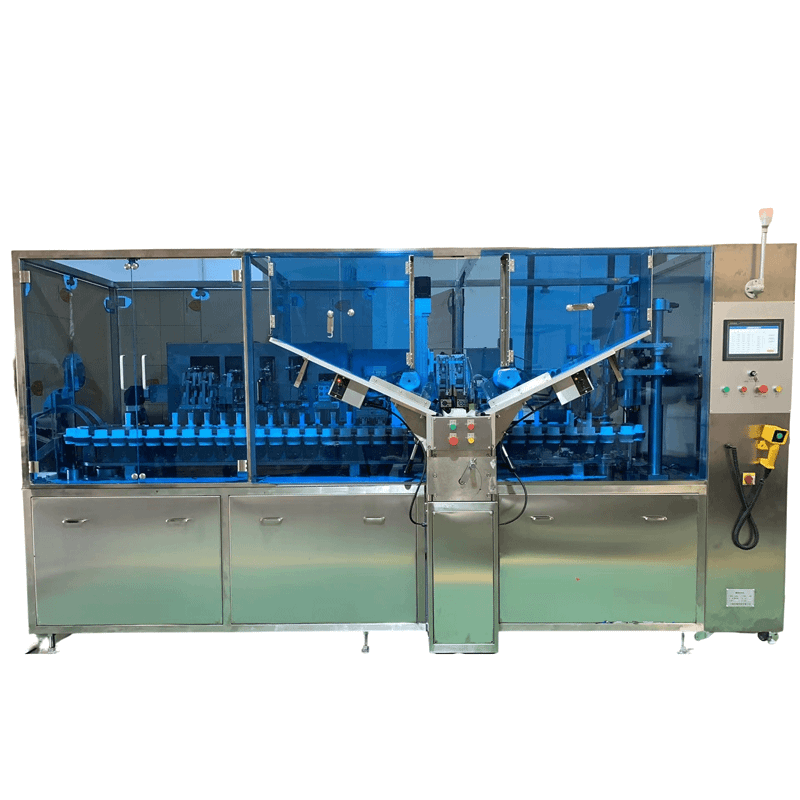

Tsis Siv Neeg Tube Filling Tshuab Series Parameter Sau.

Rau peb lub raj filling tshuab. Peb tau dav dua 10 lub tshuab qauv rau cov neeg siv khoom xaiv. Nov yog ntawm no sau cov raj raj tshuab ceev heev rau koj siv. Peb ib txwm muab cov neeg siv khoom siv thev naus laus zis txog kev muab tub luam

| Qauv tsis tau | Nf-40 | Nf-60 | Nf-80 | Nf-120 |

| Cov Khoom Siv Raj | YAS, TXHUAS HLAU .COMPOST ALL LARHINATE HLIS | |||

| Chaw Nres Tsheb Tsis Muaj | 9 | 9 | 12 | 36 |

| Tube Diam | om13-om60 hli | |||

| Raj ntev (hli) | 50-220 tau kho tau | |||

| Cov khoom lag luam viscous | Viscosity tsawg dua 100000cpCreamp Gel Ointicit PDSit Cov Tshuaj Txhuam Muab cov zaub mov noj thiab tshuaj lom neeg txhua hnub | |||

| Peev (Mm) | 5-250ml Adjustable | |||

| Sau ntim (xaiv tau) | A: 6-60ml, B: 10-120ml, C: 25-250ml, D: 50-500ml (cov neeg siv khoom tau muaj) | |||

| Instatic Qhov Yog | ≤ ≤ 1% | |||

| Tubes ib feeb | 20-25 | 30 | 40-75 | 80-100 |

| Hopper ntim: | 30Litre | 40Litre | 45Litre | 50 Litre |

| Cua Xa Khoom | 0.55-0.65mpa 30 m3 / min | 340 m3 / min | ||

| Lub cev muaj zog | 2kW (380V / 220V 50Hz) | 3kw | 5kw | |

| Cua sov fais fab | 3kw | 6kW | ||

| Qhov loj me (hli) | 1200 × 800 × 1200mm | 2620 × 1020 × 1980 | 2720 × 1020 × 1980 | 3020 ×: × 1980 |

| hnyav (kg) | 600 | 800 | 1300 | 1800 |

Vim li cas thiaj li xaiv US rau lub raj filling tshuab

Zhitong tuam txhab ua ib qho ntawm cov noog ntim tshuab chaw tsim tshuaj paus kev cai ntau tshaj 2000 cov neeg siv khoom hauv ntiaj teb thiab peb muaj ntau qhov zoo raws li kev cuam tshuam

A.Professional technology thiab kev paub nplua nuj

Kev lag luam-coj thev naus laus zis: Zhitong tau nce siab txog kev sau thiab sib khi thev naus laus zis, uas tuaj yeem ua kom muaj kev ua haujlwm siab thiab muaj txiaj ntsig zoo sau cov raj raj ntawm raj tshuab raj.

b. Kev nplua nuj kev paub: tom qab xyoo ntawm kev sib sib zog nqus hauv lub raj raj filling thiab peb tuaj yeem muab cov neeg siv khoom siv cov kev xav tau uas zoo tshaj plaws lawv cov kev xav tau.

C.Wide qhov kev siv tau: Peb lub raj filling rau ntau yam tshuaj noj xws li tshuaj, tshuaj pleev ib ce, thiab lwm yam cov khoom lag luam sib txawv.

D.Muliple cov qauv xaiv los ntawm: Peb muab cov raj muab tub lim los ntawm: peb muab cov khoom siv raj thiab cov qauv tshwj xeeb kom tau raws li cov khoom siv sib txawv uas tsim tawm thiab cov raj sib txawv.

e. RAJ FILLING MACHINE MUAJ SIAB LOS THIAB HIGH EFFICI

F.Pe siv cov tshuab siab heev thiab tswj cov tshuab rau raj filling tus nqi yog qhov tseeb thiab txhim kho cov khoom tsim nyog rau 99.999%

g. Kev tsim tawm tau zoo: Peb lub raj ntim tshuab muaj qhov siab ntawm kev siv tshuab, uas tuaj yeem txhim kho kev ua haujlwm ntau dua, txo cov nqi ntau lawm thiab txo qis.

h. Cov Khoom Siv Zoo: Peb cov raj muab ua ke siv lub tshuab siv cov khoom siv zoo thiab cov khoom sib xyaw kom ntseeg tau tias qhov ruaj khov thiab ruaj khov ntawm lub raj muab tub luam.

I.Multiple Kev Nyab Xeeb Kev Tiv Thaiv: Lub raj filling tshuab yog nruab nrog kev tiv thaiv kev nyab xeeb, lub qhov rooj qhib kev nyab xeeb, kom muaj kev nyab xeeb thiab muaj kev ruaj ntseg ntawm cov txheej txheem ntau lawm.

j.Re greatural qauv tsim qauv: lub raj filling cov qauv tsim muaj thiab huv, thiab yooj yim rau kev tu txhua hnub thiab upkeep ntawm cov cav tov ..

k. Yooj yim rau kev ua haujlwm: Raum Foob Tshuab muaj cov phooj ywg zoo nkauj, muab tub lim yog yooj yim thiab yooj yim ua haujlwm, txo qis kev ua haujlwm thiab tus nqi ntawm kev kawm ua haujlwm.